Ball mill optimization. Dhaka, Bangladesh 21 March 2010 1 Introduction Wajananawat Experience: 13 Years (2 y in engineering,11 y in production)

Milling and micronization of particles are routinely employed in the pharmaceutical industry to obtain small particles with desired particle size characteristics. The ...

Ball milling effect on structural and magnetic ... It is clear that with increase in the milling time, particle size decreases. ... After ball milling for 1, 2, 3, ...

An introduction to particle size reduction with ball milling. Part of the Glassware Gallery.

These can be related to the Hukki relationship between particle size ... an experimental method to measure the energy used locally during milling ... Ball mill A ...

It works efficiently and takes very short milling times. HMK1901 Planetary Ball Mill is a convenient benchtop ball mill for size reduction and ... Particle Size ...

Prater provides toll milling and toll grinding for companies in need of toll processing and toll ... industrial and foodgrade material by particle size ...

How does slurry milling affect a particle size distribution? Develop a theory that predicts the impact of a slurry milling process on the particle size distribution ...

Fulltext (PDF) | Ball milling is a top down approach and a method to reduce size of particle while Zeolite is a valuable inorganic materials having wide variet...

British Rema’s range of mills and micronizers are capable of manufacturing to the most demanding particle size and sizedistribution specifications.

Why I cannot get Alumina particle in nanosize scale using ball ... can be obtained by ball milling ... particle size analyzer or TEM. 15% ...

FRITSCH is a manufacturer of applicationoriented laboratory instruments for Sample Preparation and Particle Sizing in industry and research laboratories.

What particle size range does ball mill grinding . Ball mill grinding is one method of crushing ore to an appropriate size fraction. Specifically, ore is put into a ...

Jar, Ball and Pebble Milling . Theory and Practice. ... milling is a process for reducing the particle size of solids to some required degree of subdivision.

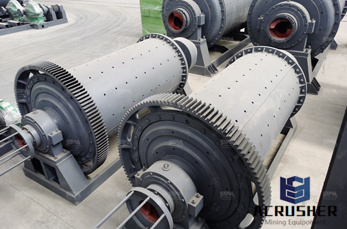

Ball Mills are used for the particle size reduction of a wide variety of materials. In a range of sizes and often used in high volume applications.

Preparation of Micrometer to SubmicrometerSized Nanostructured Silica Particles Using HighEnergy Ball Milling ... 18 After 10 min of milling, the particle size

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL ... Ball size distribution inside an industrial mill was analysed in ... Product particle size distribution ...

A model describing the mechanical comminution (ball milling) of crystals to nanocrystalline powders is proposed. It is shown that .

ball mill particle size ... EFFECT OF BALL MILLING PARAMETERS ON THE PARTICLE SIZE 829 contains q interatomic bonds, each with the binding » Learn More.

AVEKA%u2019s ISO 9001:2008 certified facility features both media particle grinding and milling equipment including ball mills and bead mills, and medialess particle .

Ball milling is a size reduction technique that uses media in a rotating cylindrical chamber to mill materials to a fine powder. Contact us today!

Particle size and distribution: (i) ... Evaluating the Use of Ballmilling on the Douglasfir Particles ... FIGURE 22 Effect of ball milling (a) ...

EFFECT OF BALL SIZE DISTRIBUTION ON MILLING PARAMETERS ... Batch grinding tests on single ball sizes 82 Particle size .

... the smaller the particle size of the ... Ball milling boasts ... mill called a planetary ball mill. Planetary ball mills are smaller than common ball ...

WhatsApp)

WhatsApp)