Megatech Exporter and supplier of clinker grinder, clinker grinder unit, clinker grinders, clinker grinder units, manufacturing process for cement, clinker ...

Overview of cement milling, ... As part of the grinding process, ... reactions in the kiln and cement milling: Cement notation / Clinker compositional parameters ...

CEMENT GRINDING OPTIMISATION ... in the cement industry, the grinding process is more of ... The cement clinker grinding circuit reduces the feed from 80% passing ...

Video embedded· Learn cement manufacturing process thoroughly. ... several dry process cement plants are vying with each ... The clinker temperature at .

Metallurgical Content1 RAW CEMENT GRINDING2 WET VS DRY Grinding of Cement3 CLINKER GRINDING4 Cement Grinding Mills5 High Efficiency Cement Grinding .

What is the purpose of adding gypsum in cement? Civil Engineering. During the cement manufacturing process, upon the cooling of clinker, a small amount of gypsum is ...

Clinker grinding is a decisive, energyintensive step in the cement production process. Vertical mills and tube mills that grind cement clinker at a maximum output of ...

Cement Plant Equipments: We known for quality equipments manufactures and supplier of clinker grinding units, rotary kilns, crushers, conveyors for cement plants in ...

Introduction of cement processing flow inclurock cement crushing, Grinding, and clinker Grinding. CGM provides you with cement production process machine of .

Production Process. Cement production is a precise and controlled activity. It involves the transformation of the raw materials (from predominantly natural sources

The cement clinker grinding process is wellknown within the traded of mining, building supplies, chemical engineering and metallurgy for size reduction,dispersion,or ...

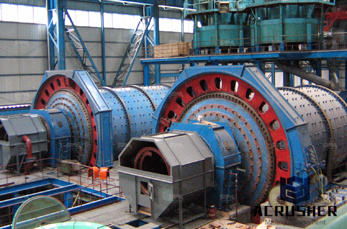

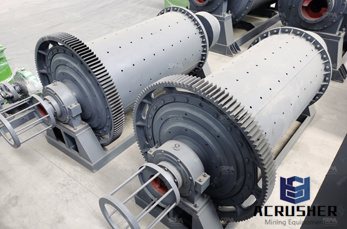

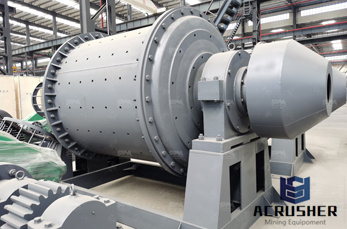

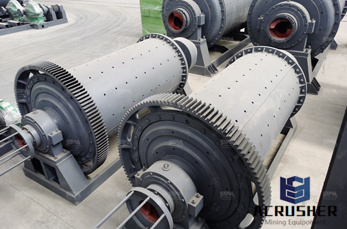

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Cement processing mainly consists of the following steps: crushing, prehomogenization, homogenization of raw materials, decomposition through preheating, clinker ...

Cement clinker equipment manufacturer. Shanghai SBM provide you crushing machine and grinding mill for the cement clinker process, the cement manufacturers paying for ...

Kenya Cement Clinker Grinding Process Machine Supplier. Cement Clinker Grinding Process Machine industry as Kenya mining equipment industry an important part, yet ...

Cement; Cement Clinker; Production Process; ... In the manufacture of Portland cement, clinker is the solid ... Manufacturers also ship clinker to grinding plants in ...

Manufacturers of Clinker Grinding Unit in India. ... Name Of The Material: Properties: 1. Clinker2. 75% min. ... Mini Cement Plant | Clinker Grinding ...

Cement Manufacturing Process ... Clinker cooling | Cement making process. ... This fine powder is considered as cement. During grinding gypsum is also added to the ...

Clinker Grinders Processing plant Specification Clinker Grinders Processing plant is the key equipment for grinding after the crushing process, which is widely used ...

Manufacturing Process < About Cement < Cement: ... ready for grinding, to produce cement. ... is added to the clinker to regulate how the cement will set.

Clinker Grinding Mill is the key equipment for grinding after the crush process, and it is widely used in the manufacture industries, such as cement, silicate, new ...

Clinker grinding process and cement properties improvements by additives . M. Goisis *, ** * Italcementi, Italcementi Group, Innovation Department, via ...

Aug 26, 2016· ... raw material grinding, clinker, cement grinding. ... It is an inorganic material cement raw material grinding process cement raw material grinding ...

Cement Manufacturing Process Raw Materials The hydraulic ... Finish Mill The final process of cement making is called finish grinding. Clinker dosed with controlled ...

WhatsApp)

WhatsApp)