Cement mill Wikipedia, the free encyclopedia A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into .... most efficiently by making a coarse product, the fine fractions of this then being ...

Influence of the ball filling factor on the power consumption and throughput of ball mills in combined grinding plants [Einfluss des Kugelfuellungsgrades auf ... Combined grinding plants have been used increasingly in the last few years ...

Optimum choice of the makeup ball sizes for maximum throughput ... Jun 27, 2013 ... The ball size is one of the critical factors for determining the mill ... The breakage of a uniformly sized particle results in the production of an...

influence of clinker on the mill throughput . Holcim Ternate plant, Italy, where clinker production was increased ... The figures for clinker grinding are again comparable with those ... the energy costs ... Get Price Online » ...

calculate ball mill throughput in closed circuit [ 8237 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our Related Posts » » ...

ball mill throughput calculator YouTube Dec 16, 2013 cement ball mill throughput calculation; please go to the following calculator: Cement mill sizing; Ball charges calculators; Volume load; Get Price Online Free Online ...

The influence of grinding technique on the liberation of clinker minerals and cement properties. Author links open the author workspace. Celik Opens the author workspace Opens the author workspace. Author links open the M. ...

Home»Products»influence of clinker temperature on cement grinding influence of clinker temperature on cement grinding Posted at: May 11, 2013 [ 6473 Ratings ] effect of clinker temp in cement grinding Thus the influence . ...

The ball size in a mill has a significant influence on the mill throughput, power ..... of grinding ceramic bulk considering grinding media contact points,. Ceramic Grinding Media alyst Media :: CoorsTek Technical Ball Mill Grinding ...

Reducing the Energy Required in Grinding Clinker to Cement – Some Case Studies H Benzer, N Aydogan, H Dundar and AJ Lynch August 28, 2011 Publications MetPlant 2011 Grinding clinker to finished cement consumes more ...

Modern Applied Science; Vol. 8, No. 6; 2014 ISSN EISSN Published by Canadian Center of Science and Education 296 Intensification of Cement Grinding with Apply Grinding Aids with Modify Effect Lyubov ...

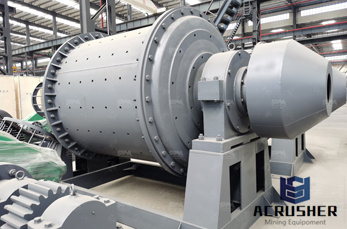

Optimization of Cement Grinding Operation in Ball Mills Contact Us » Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and ...

2001/10/02· the influence on mill performance the economics involved the quality characteristics and customer objectives any environmental concerns These are discussed in the following sections in more detail. 10. CEMENT C E M ...

THE ANNALS OF "DUNAREA DE JOS" UNIVERSITY OF GALATI FASCICLE XIV MECHANICAL ENGINEERING, ISSN 2007 THE GRINDING CHARGE OF ROTARY MILLS Gh. Ene "Politehnica" University of ...

Cement Mill Ball Mill Dynamics Kiln Control Theory Burning Dashboard Refractory Reference Bag Filters ... The use of a finer ball charge results in a higher mill retention time and finer grinding giving a lower mill throughput (and ...

Design and Optimization of Ball Mill for Clinker Grinding in Cement Plant. Sanjeev T. Patil grinding in ball proposemore precise empirical equation for modified HGI relating Grinding media are ceramic and steel balls of 10 ...

clinker as well as the cement, is obtained by grinding in of the combined effect striking and friction. The correct . critical speed of this, when grinding. [Get Price...] Ball Mill Critical Speed Working Principle . The effect of Ball ...

ABB drives in cement Medium voltage drives for reduced, Furthermore, cement production is very energy intensive Much of the, impact on a company''s operating costs Fixed versus, processes require a lower grinding throughput, the ...

8 Polysius roller mills.....for raw material grinding. øC A B Roller mills from Polysius efficiently grind all raw materials for the clinker manufacturing process – ranging from soft to very hard, from dry and fine to very moist and sticky ...

Clinker grinding test in a laboratory ball mill using clinker burning with petcoke and coal 31 | Page mentioned in the literature .

Mill optimization Grinding makes up a big portion of the electrical energy consumed on the plant, thus the efficiency of grinding operations has a big influence on your energy bill. EO optimizes your grinding circuit to increase ...

US EPA Alternative Control Techniques Document Update NOx. 91 Effect of SNCR on Emissions with Staged Combustion.. .. clinker are typically limestone, sand or silica, clays, mill scale, and fly ash. The major throughput ...

Design and Optimization of Ball Mill for Clinker Grinding in Cement Plant, for broad based application for variety of minerals processing represented by HGI = 13 + 10 m (1) For clinker, it is HGI = 3050 and grindability values range ...

2017/08/05· The following are the basic TEN FACTORS which are having a direct influence on the mill performance. Therefore knowing them is of the primary duty for the person assigned for "Mill Optimization". 1 2 . but below their natural grain ...

WhatsApp)

WhatsApp)