How to optimize a 6 pound ball mill to safely and effectively ball mill homemade black powder.

Ball Mill Principle of Mechanical Unit Operation Report on Ball Mill Submitted to We discuss the types of ball mill, the basic principles of the ball mill,

KLAREN BV Inventors selfcleaning heat exchange technology 2 Figure 1: Principle of selfcleaning heat exchanger. Abstract. A new development in fluidized bed non ...

The PMCE Evaporative Condenser product line is a combination of EVAPCO''s extensive forced draft evaporative cooling product experience and engineered solutions ...

PRINCIPLE: A ball mill works on the principle of impact and attrition. ... The principle of operation of the conical ball and pebble mills is the same, ...

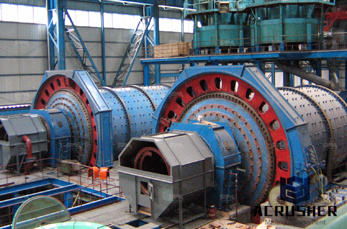

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

ball mill principle of operation. Ball Mill Working Principle. Ball Mill Working Principle. Ball mill is a horizontal cylinder, in and out of the hollow shaft and ...

principle of the ball mill. ... A ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, ...

Principle of Operation. The mill operates as a wet circuit ore suspended in water ... Download the Operational Principle of Ball Mill (PDF) Ceramic Media

Online daily paper of Galveston, Texas.

Working principle of Ball Mill /ball cement ... Said disadvantages are caused by the fact that the design and principle of operation of the mill of such type do not ...

End mills (middle row in image) are those tools which have cutting teeth at one end, as well as on the sides. The words end mill are generally used to refer to flat ...

DMIC Ball Valves Catalog DBV0101E Call Toll Free BVAL ...

The DMQX bead mill from Union Process provides highly effective, reliable circulation grinding, producing uniform fine dispersions with superior product quality.

2 K Table Of Contents Preface Introduction History Typical Applications Section I Hydrodynamic Bearings Hydrodynamic Principle Basic Pivoted Shoe Thrust ( Journal) .

Planetary Ball Mills are used wherever the highest degree of fineness is required. Powerful and quick grinding down to nano range. Read more.

Attritors and Ball Mills How They Union Process. May 9, 2000 In this presentation we will discuss the principle of the Attritor and its appliions.

Ball Mill Working Principle Ball Mill Working Principle. Ball mill is a horizontal cylinder, in and out of the hollow shaft and grind the first parts.

Principle of Operation. The refrigerant is circulated through the coil of the evaporative condenser. Heat from the refrigerant is dissipated through the coil tubes to ...

Sep 17, 2013· This video provides an overview of how to perform Critical Path Method (CPM) to find the Critical Path and Float using a ...

The Planetary Ball Mill PM 100 CM ... Safety Slider for safe operation; ... This innovative FFCS technology is based on the d''Alembert principle and allows very ...

Complete package that includes: a) machine simulation teaches the student the setup and operation of CNC machines. b) CNC program simulation and gcode debugger ...

The Planetary Ball Mill PM 200 is an excellent choice when a high degree of fineness is required. Grinding down to the nano range. Read more.

Jan 26, 2013· Basic principle and practical procedure of the Charpy impact test Testing machine, test specimen Basic principle, impact energy measurement ...

WhatsApp)

WhatsApp)