"BEST AVAILABLE TECHNIQUES" FOR THE CEMENT INDUSTRY. CEMBUREAU the European Cement Association, based in Brussels, is the representative organisation for .

PENTA Engineering Corp. completed a cement plant raw mill and kiln conversion project at Hagerstown for LafargeHolcim.

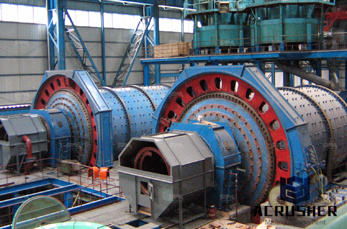

Raw ore mill is the key equipment for grinding after the crush process, which is widely used in manufacture industries, such as cement, silicate, new building ...

Raw Mill Is Widely Used In Cement Plant. Raw mill is the key equipment for secondary grinding after crushing. And it is suitable for grinding all kinds of ores and ...

Cement Raw Mill, Wholesale Various High Quality Cement Raw Mill Products from Global Cement Raw Mill Suppliers and Cement Raw Mill Factory,Importer,Exporter at ...

In the cement industry, natural raw materials are processed to produce an end product which is a fine powder. As shown in the flow diagram, ... Raw material mill.

Cement mill Wikipedia, the free encyclopedia. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from ...

Laxmi Engineering Work :: Mini Cement Plant. Reducing the strain on the transport system, as most of the cement manufactured can be consumed in the nearby market.

A vertical raw mill is mainly used in cement plants for raw material grinding. Cement manufacturing components of a cement plant. Cement manufacturing process ...

Whether ball mill or vertical roller mill (VRM), A TEC offers the expert solution for efficiency optimization to increase mill productivity and/or reduce mill power...

Brief description of a cement mill. ... Raw materials; ... Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ...

Loesche to deliver three VRMs to Sohag plant. ... a raw material mill with a capacity of 540tph of cement raw meal, a 350tph cement mill as well as a coal mill with ...

A cement mill (or finish mill in North American usage) ... These have been used for many years for the less exacting rawmilling process, ...

The LOESCHE scope of delivery includes a raw material mill with a capacity of 540 t/h of cement raw meal, a cement mill with an output of ... CEMENT RAW MATERIAL

There are many process fans that find applications in cement industry such as raw mill fans, induced draft fans, ... Process Fans Used in Cement Industry

Portland Cement Manufacturing ... In the wet process, water is added to the raw mill during the grinding of the raw materials in ball or tube mills, ...

Raw Mix Preparation Raw Mix Optimization ... material proportions in the raw mill feed. As in ... • cement is ground to high quality from consistent clinker

The ATOX Raw Mill is a highly efficient mill that grinds all types of raw materials – saving both space and energy while delivering outstanding performance

The raw material preparation stage of cement manufacture results in the production of a rawmix that is ... The nearly universal use of roller mills for raw milling ...

As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including ...

working principle. This cement mill is widely used in the grinding of cement raw meal, slag(GGBS plant), cement clinker, raw coal and other raw materials.

Raw / Cement Mill, Cement/ Raw Mill – IndiaMART – Indian . This range of industrial machinery is manufactured using premium quality for Raw / Cement mills With ...

IMPROVED CEMENT QUALITY AND GRINDING,, consisting of a tube ball mill and a high efficiency separator was introduced through,, Finish Mill Kiln Raw Mill Raw Mix ...

Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particles. Vertical raw mills are widely used in the concrete and ...

WhatsApp)

WhatsApp)